Swiss Made functional sapphire

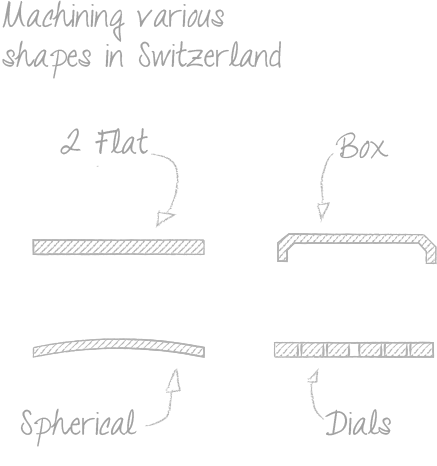

Thanks to flawless collaboration with the best Swiss sapphire manufacturers, ECONORM also offers its services in the development and production of end products, from the purchase of 100% Swiss sapphire to its decoration right down to the smallest detail.

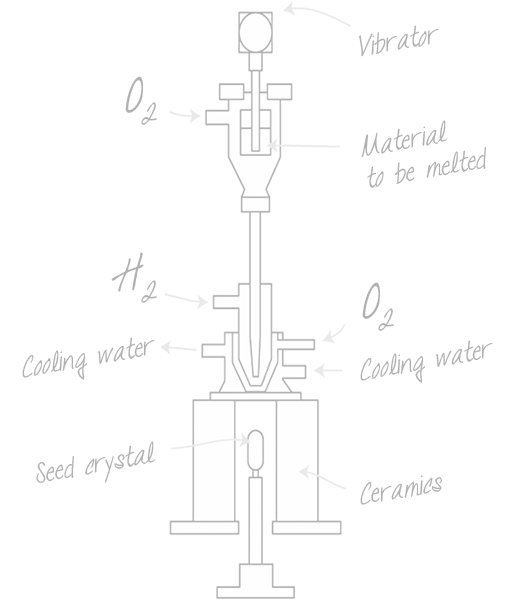

Sapphire production

100% Swiss Sapphire

TIMSAPH SA uses a technique for the production of sapphire based on the « Verneuil » which produces sapphire drop by drop from alumina powder melted by a hydrogen flame (temperature above 2,000 °C).

TIMSAPH SA enjoys the benefit of state-of-the-art technology allowing ultra-fine adjustments in gas and powder diffusion. These exclusive and sophisticated machines ensure both good internal and external quality of the sapphire (regularity of shapes and sizes).

A functional sapphire

SAPHIR ARunic®

≤ 3% (Raw sapphire ~14%)

-

Hardness

≥ 2'000 HK0.3

×Hardness

Constant hardness, guaranteed resistance to everyday impacts and longterm product stability in line with standards NIHS 61-13 and SN EN ISO 4516: 2002.

-

UV filter

From 410 nm

×UV Filter

Blocks UV rays completely from 410nm avoiding premature aging of the watch’s internal oils and decor.

-

High resistance to wear

LC1 ≥ 50 mN

LC2 ≥ 70 mN×High resistance to wear

The Nano Scratch Test (NST3) shows minimum (LC1) and maximum (LC2) scratch resistance in line with ISO 20502 and DIN EN 1071.

-

Achromatic

Limiting angle: 30°/35°

-

Antistatic

20 - 150 kΩ

×Antistatic

As far as possible, it is important to avoid any dust getting inside the glass in order to facilitate the latter’s use during the assembly process, as well as taking account of the static constraints detrimental to the proper functioning of the watch.

-

Ease of maintenance

Contact angles: ≥ 80°

×Ease of maintenance

Facilitates cleaning of the glass to preserve a clear and precise vision of the dial at all times.

We measure this value with the help of ethylene glycol.

SAPHIR ARdur®

approx. 4% (raw sapphire ~14%)

-

Extreme hardness

≥ 2'000 HK0.3

×Extreme hardness

Constant hardness, guaranteed resistance to everyday impacts and longterm product stability in line with standards NIHS 61-13 and SN EN ISO 4516: 2002.

-

Extreme resistance to wear

LC1 ≥ 50 mN

LC2 ≥ 70 mN×Extreme resistance to wear

The Nano Scratch Test (NST3) shows minimum (LC1) and maximum (LC2) scratch resistance in line with ISO 20502 and DIN EN 1071.

-

Achromatic

Angle limit: 30°/35°

-

Antistatic

20 - 150 kΩ

×Antistatic

As far as possible, it is important to avoid any dust getting inside the glass in order to facilitate the latter’s use during the assembly process, as well as taking account of the static constraints detrimental to the proper functioning of the watch.

-

Ease of maintenance

Contact angles: ≥ 80°

×Ease of maintenance

Facilitates cleaning of the glass to preserve a clear and precise vision of the dial at all times.

We measure this value with the help of ethylene glycol.

Decoration

Solution-oriented, we adapt to the needs and constraints of each customer and offer them a wide range of metallization options. From simple applications for small inscriptions to highly specialized coatings for shaped crystals, our structured metallized coatings meet every need.

Let's talk about your project

ECONORM AG - Gams

Production and R&D

Industriestrasse 6

CH-9473

Gams

Telephone 081 750 32 10

ECONORM AG - Saint-Imier

Prototyping and HQ

Rue Pierre-Jolissaint 35

CH-2610

Saint-Imier

Telephone +41 32 910 22 33

Fax +41 32 910 22 34